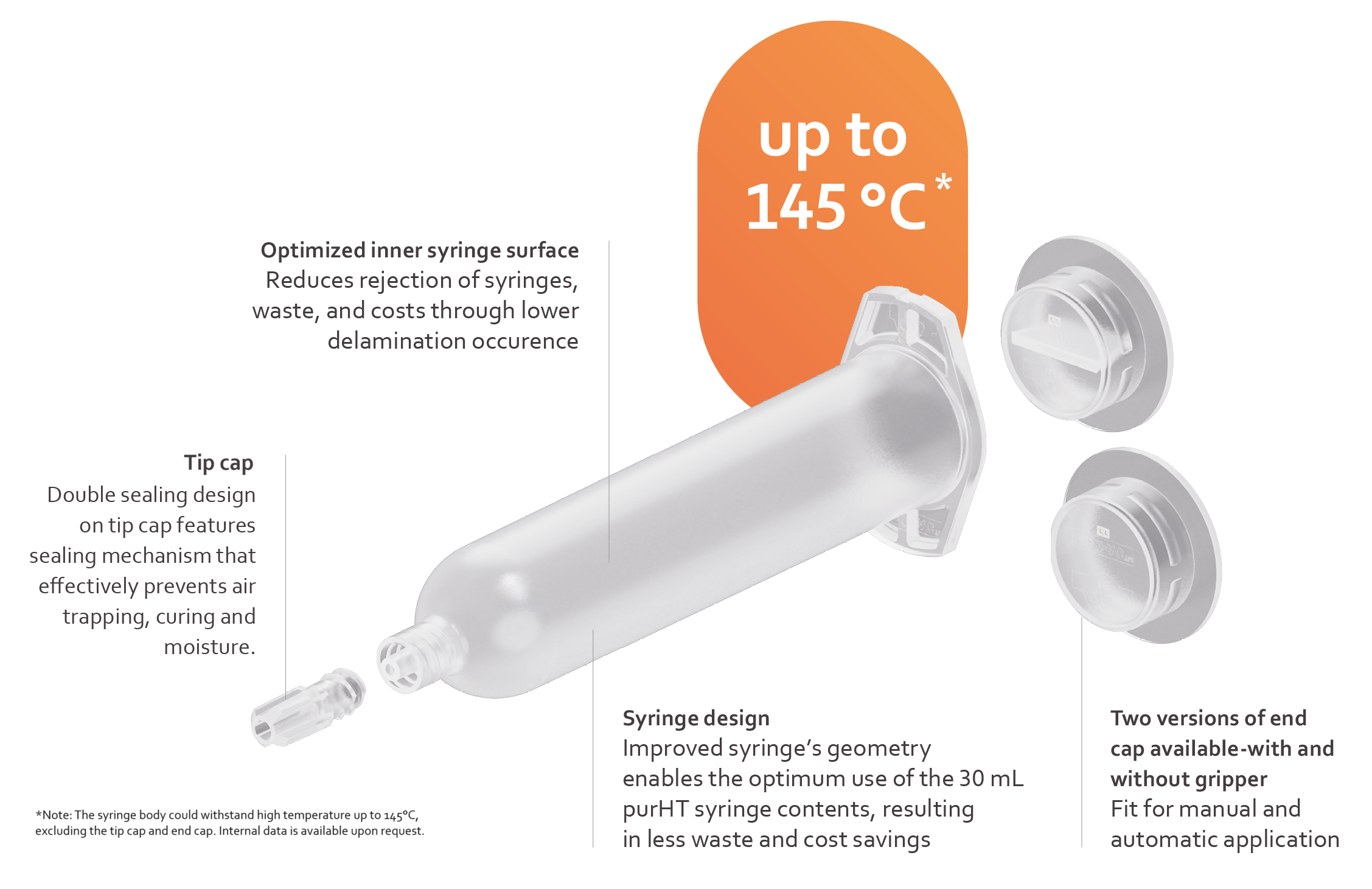

30mL purHT™ syringe kit

For one-component PUR hotmelt applications up to 145°C

MIXPAC™ is the leading system provider in the area of mixing, dosing and applying for industrial applications.

LONGER OPEN TIMES AND HIGHER PROCESS EFFICIENCY

With the new 30mL purHT syringe kit, medmix offers you and your customers the ultimate in performance: Featuring a higher heat resistance, the superior 30mL syringe ensures longer open times and a better workflow in semi-automated processes. Designed for a better chemical resistance to reduce delamination, an improved air tightness to reduce curing material and higher translucence to avoid black spots, the one-component cartridge helps to save costs, time and waste!

PERFORMANCE

Save costs and increase your process safety

FEATURES

MIXPAC 30mL purHT Syringe Kit

See why you should try MIXPAC purHT:

- Double sealing

- Up to 145°C heat resistance

- Flexible option with 2 end caps (for manual and automatic handling)

Test yourself ...

BENEFITS

Made for the most advanced hotmelt solutions

- High-performance applications

30 mL purHT syringe kit meets the highest demands of semi-automated bonding processes with economical dosing machines, e.g. for mobile phones and many other electronic devices. - Longer open times

With its higher heat resistance, the 30 mL purHT syringe kit enables end users to achieve longer open times for dispensing by increasing equipment temperature. - Time and costs savings

The chemical resistance of the syringe reduces delamination and helps reduce the rejection rate, time and costs. - One version for all

One single syringe version covers applications up to 145°C, streamlines pack matching and optimizes inventory management. - Reduced rejects

Improved visibility enables the detection of minor material quality flaws and allows you to reduce false rejects, reduce waste and costs. - Reduced cured PUR

The optimized air-tight design of the syringe with proprietary tip cap and end cap leads to less waste/cured material.

High-performance applications

30mL purHT syringe kit meets the highest demands of semi-automated bonding processes with economical dosing machines, e.g. for mobile phones and many other electronic devices.

“Our technology and system know-how is now available for an alternative one-component solution.”

Gerry Hernandez Head Global Product Management

medmix

Expert in two component and one component systems

With almost 100 years of experience, medmix stands for world leading mixing and dispensing systems. Partnering with us leads global OEMs to stable and scalable quality processes. They profit from leading technology, a comprehensive injection molding know-how and our 360-degree competence for both two component and one component systems.

Contact

Get your free purHT sample!

Do you want to know more about purHT and its benefits for your hotmelt bonding solutions? Get in touch with us for more information, request your personal offer or get your free sample.