Contract Filling

High precision filling services are available utilizing fully-automated production lines for dental liquids and composite resin materials.

Over 15 years of experience make us an excellent partner for contract filling.

medmix provides SPECIFIC FILLING SERVICE SOLUTION for customer materials (e.g., composites, desensitizers, bonding agents, varnishes, etc.) in primary containers (unit dose containers, composite capsules, syringes) in combination with labeling (printing on container) according to customers` specific requirements.

① DELIVERY SYSTEM

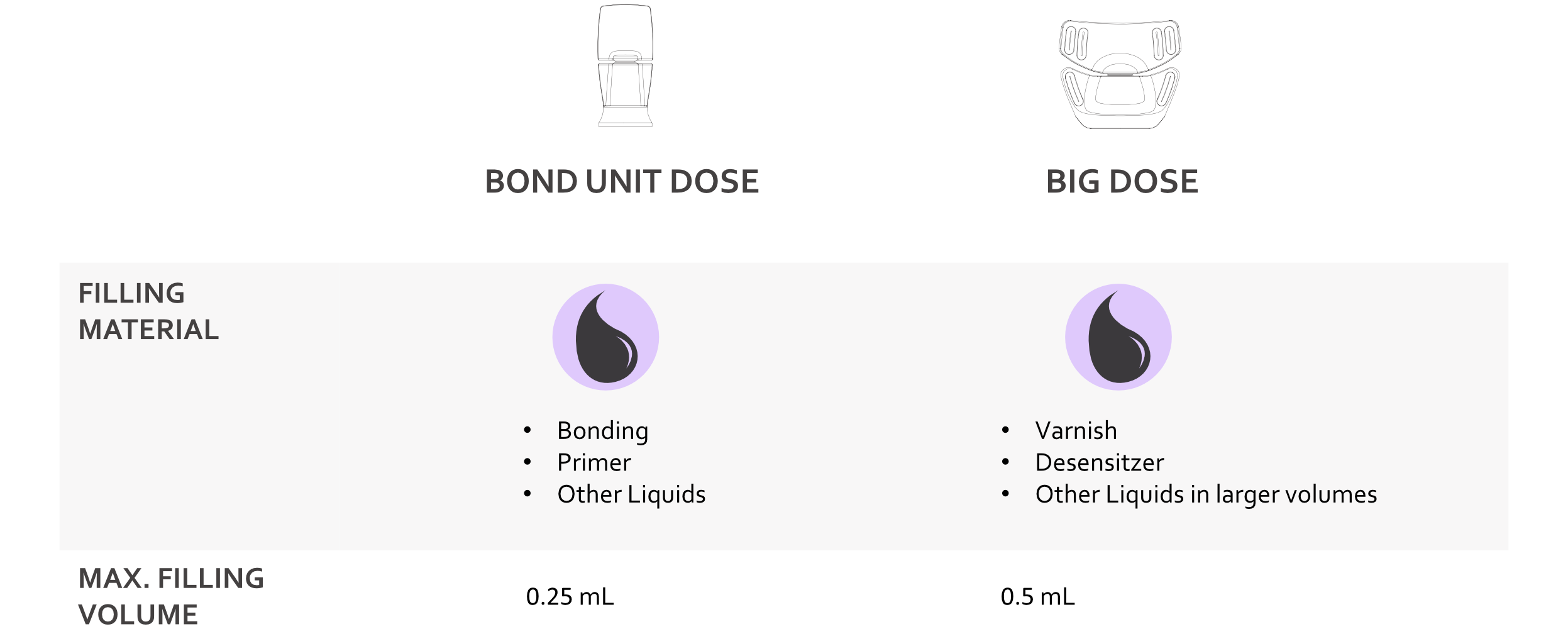

Selection of the delivery system for your bulk material:

- Unit Dose (liquids, adhesives)

- Capsules (high/low viscosity composites)

- Big Dose (liquids, adhesives, varnish)

Definition of the product parameters:

- Filling volume

- Color of Unit Dose

- Printing layout

③ SERIAL FILLING

After approval of the trial samples and product specification, the serial production filling process is started using an established qualification and validation process to guarantee consistent quality for each batch.

② TRIAL RUN

Testing of the filling equipment with your bulk material to:

- determine optimal filling process parameters

- determine optimal filling process parameters

- define the tolerances

- provide prototypes for stability and pre-market evaluation

④ KIT PACKAGING

As an additional service, medmix can support:

- implementing your design

- assembly of "ready to sell" kit packaging (including the shipping box container)

- instructions for use and technique card (using the artwork provided)

Related products

Composites & flowables

Pastes & gels

Related pages

Customized packaging

We can support all of your packaging needs.

Customized printing

Customize your MIXPAC product using one of our well-established printing solutions.