Introduction in Mixing Technology

medmix is the original for innovative one- and two-component system solutions used to accurately mix, dispense and apply different types of dental materials for a variety of applications fields in prosthetics, adhesives, restoratives, prevention, esthetics and endodontics. Especially, two-component materials are increasingly popular due to their unique properties, and static mixers are commonly used to mix these materials before application.

Using static mixers offers the advantage of consistent mixing of two-component materials, regardless of the operator. This results in reproducible mixing outcomes and high reliability due to the absence of moving parts. Static mixers with high mixing efficiency achieve the required mixing quality with minimal discharge force and mixer volume. However, when selecting the optimal mixer technology, it is important to consider not only the mixer itself but also the rheological properties of the material, the specified mixing ratio, and the viscosity ratio of the individual components.

1.1 Mixing principles in laminar flow regimes

The materials to be mixed in dental applications are often highly viscous. This high viscosity, combined with a low flow velocity in static mixers, means that a laminar flow regime is always present in static mixers in the intended applications.

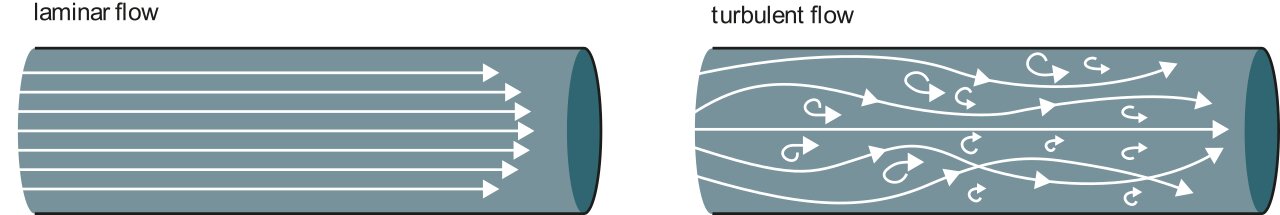

Figure1 - Left: Laminar Flow, Right: Turbulent Flow

Figure1 - Left: Laminar Flow, Right: Turbulent Flow

Laminar flow means that there are no turbulent eddies, which would also additionally allow for mixing perpendicular to the main flow direction (Figure 1). Therefore, in laminar flow mixing happens by convective and dispersive mixing, only.

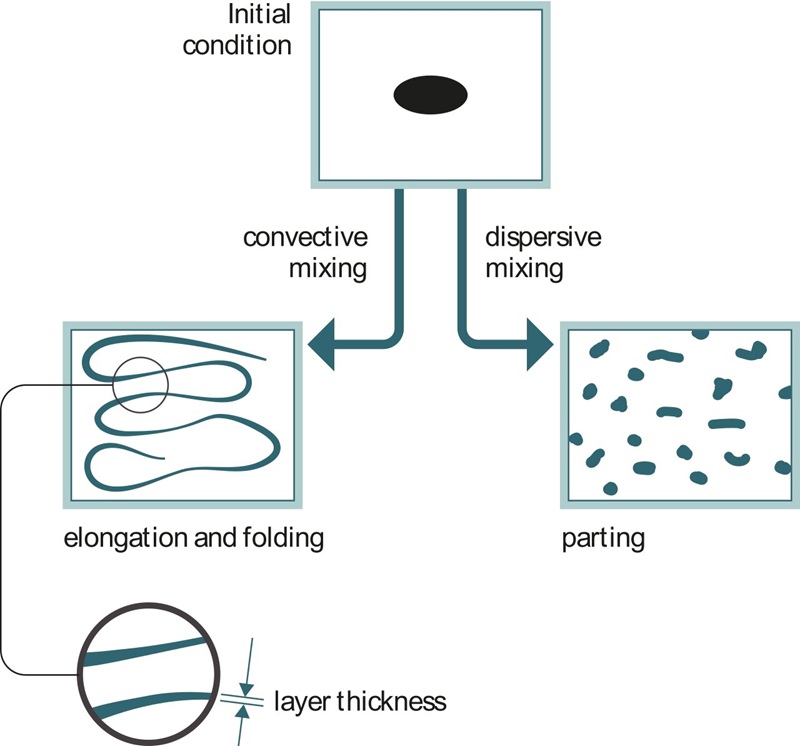

Convective mixing refers to the elongation and folding of the fluid caused by convective shear forces, while dispersive mixing means the repeated parting of the fluid at the walls of the mixer geometry. An efficient mixer geometry combines both processes in an optimal way to generate increasingly thinner layers of the components, thereby increasing the interfacial area between them (Figure 2).

The speed and quality of the curing reaction depends on the size of the interfacial area and on the relevant concentration gradients. Because the chemical reaction process is closely related to quality of mixing, it is advisable to consider the appropriate mixing technology during the early stages of developing new 2K materials.

Figure 2 - Illustration of dispersive and convective mixing

Figure 2 - Illustration of dispersive and convective mixing

1.2. How do we implement these principles in medmix mixers?

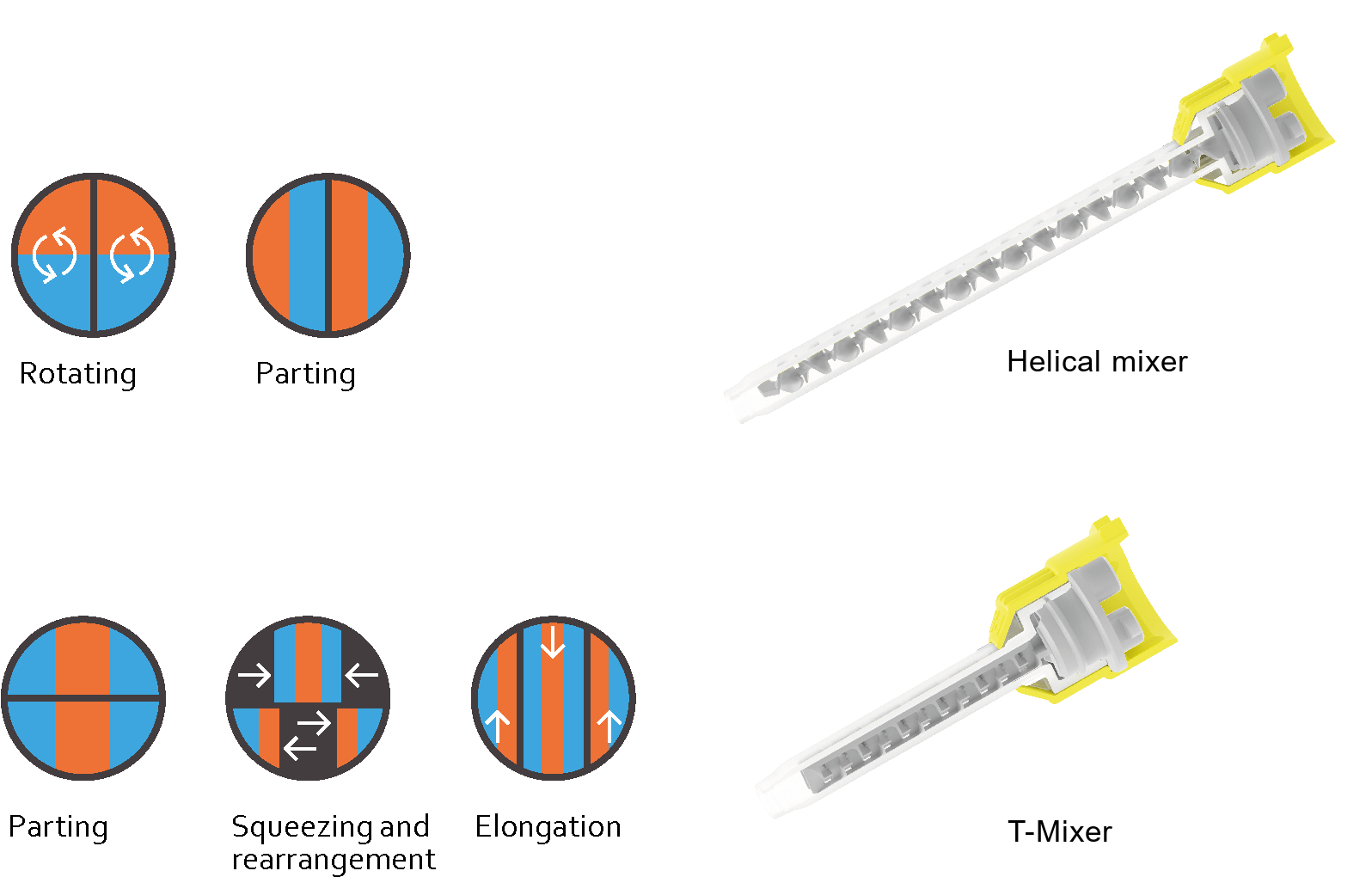

medmix is a leading supplier of mixing and application solutions for the industrial and dental markets and offers a wide range of mixer types in various sizes. Our standard Dental mixers (Figure 3) use different processes to part in half and re-orient the flow and thus the components to mix. The Helical mixers rotates the flow, while the T-Mixers squeeze, rearrange and elongate it. The mixing processes within T-Mixers are more efficient than those of the Helical mixers, resulting in lower waste volume for similar mixing quality and extrusion forces.

However, a common feature of all three mixer technologies is that the number of theoretical material layers doubles, or the layer thickness halves, with each mixing element. For instance, a mixer with 12 mixing elements results in 4096 material layers (212), which are typically invisible to the naked eye.

The customer can select the most suitable mixer for their application based on the material properties, particularly viscosity and viscosity ratio, as well as the mixing ratio and operating conditions such as flow rate and dispensing device.

Figure 3: Different mixer designs and their mixing principles

Figure 3: Different mixer designs and their mixing principles

About the author:

"Joachim Schöck has been working as a senior technology expert at Sulzer Mixpac and medmix Switzerland AG for 12 years. His main activity is the optimization and further development of high-precision application and mixing systems. This is done to a large extent using modern simulation tools such as CFD and FEM. Another focus is on the further development of test methods for predicting the mixing quality of 2K adhesives and sealants."

MIXPAC is the original for innovative one- and two-component system solutions used to accurately mix, dispense and apply different types of dental materials for a variety of applications fields in prosthetics, adhesives, restoratives, prevention, esthetics and endodontics. Especially, two-component materials are increasingly popular due to their unique properties, and static mixers are commonly used to mix these materials before application.