Numerical Flow Simulation of mixers

Flow simulations or CFD (Computational fluid dynamics) is a well-established method for analyzing and solving problems that involve fluid flows with the help of computers. This method allows for the virtuell examination of the internal or external flow field of a product before a physical prototype is produced. It enables a realistic analysis of a design version and, if necessary, optimization through constructive adjustments. Ideally, only a few necessary tests are carried out later. Thus, CFD simulations can accelerate development cycles and lead to a reduction in development costs.

1.1.Introduction to CFD

CFD involves the numerical solution of the governing laws of fluid dynamics. The complex partial differential equations are solved in geometric domains that are divided into small volumes, commonly referred to as a computational mesh.

The purpose of this article is to provide an overview of the setup and use of a typical CFD simulation in the product development process of mixing and applicator systems.

In general, a typical CFD analysis consists of three steps:

- Pre-processing phase

- Execution of the simulation

- Post-processing of the results for visualization, parameter extraction and optimization

1.2.Pre-processing

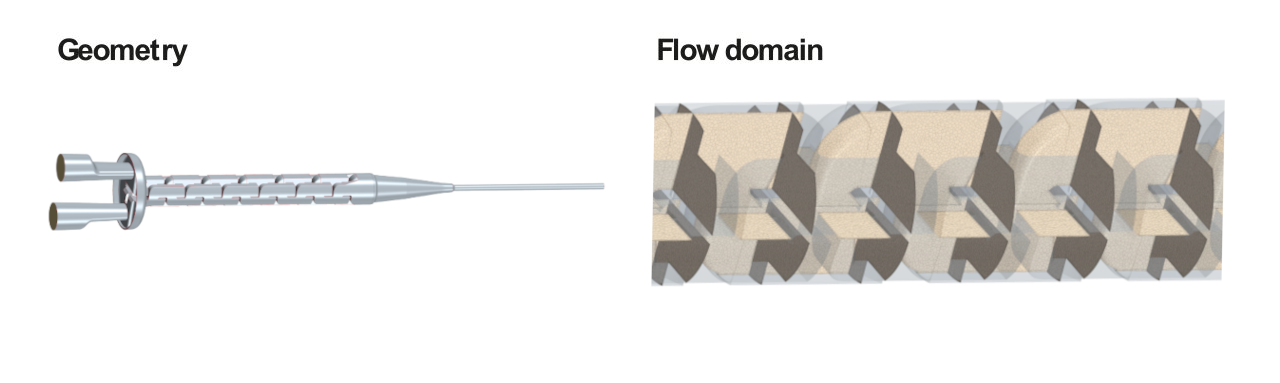

The keyword pre-processing includes all activities that are carried out before the actual simulation is executed. This starts with the use of computer aided design CAD (computer aided design) to build up the geometry and suitable physical boundaries of the problem.

Geometry preparation and simplification: From there, the fluid volume to simulate has to be extracted. During this step it is often useful to remove geometrical details that are not important for the intended analysis. For example, this can be small holes, radii or gaps without flow. The aim of this work is to reduce the complexity of the model and to focus on the essential details in order to ultimately reduce analysis time and costs without losing accuracy.

Discretization: In the second step the volume occupied by the fluid is divided into discrete cells (the mesh). The mesh generated should be fine enough to cover the major physical effects. The type of mesh should be advantageously hexahedral-dominant or at least of polyhedral type. Simple tetrahedral meshes are not adequate to obtain appropriate results.

Physical models: Depending on the type of problem to be solved during an investigation, simulations with different complexity in terms of physical models and numerical effort can be carried out. In the easiest case a steady state solver is used to simulate the flow of an incompressible and isothermal fluid in laminar flow. Multi-component or multi-phase models can be added to cover the flow of several components in one fluid domain. In the case of low viscous materials, a turbulence model has to be switched on. To solve time-dependent effects or flow fluctuations a transient solver has to be taken.

Boundary condition and fluid properties: The last step includes the definition of the fluid properties of all fluid involved. In simple cases this is the fluid density and the fluid viscosity. In more sophisticated cases with heat transfer and multiple materials this can also be thermal expansion, heat capacity, surface tension and contact angle. Operating and initial conditions are defined at the boundaries of the simulation domain.

1.3.Execution of the simulation

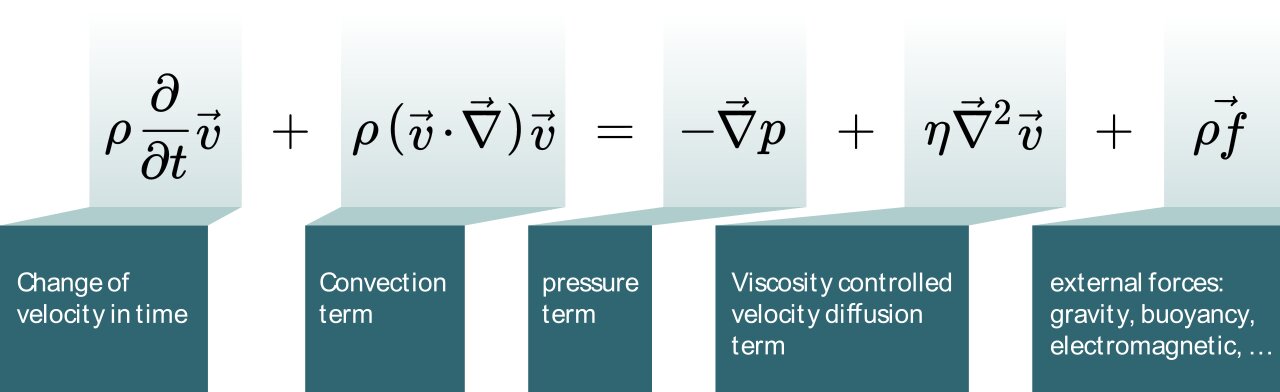

To run the CFD simulation, the so-called Navier-Stokes equations have to be solved. In physics, the Navier–Stokes equations are partial differential equations which express the conservation of mass, momentum, energy and additional scalar fields.

Figure 2 - Convective form of Navier-Stokes momentum equation

Figure 2 - Convective form of Navier-Stokes momentum equation

1.4. - Postprocessing

Postprocessing refers to the evaluation of the CFD simulation results. This can be done graphically in terms of contour, vector or streamline plots, videos or quantitatively by data tables of values. Like for all numerical simulations it is suggested to prove the plausibility of the numerical results. This can be done by comparing them with rough hand calculations or measurement data of similar designs.

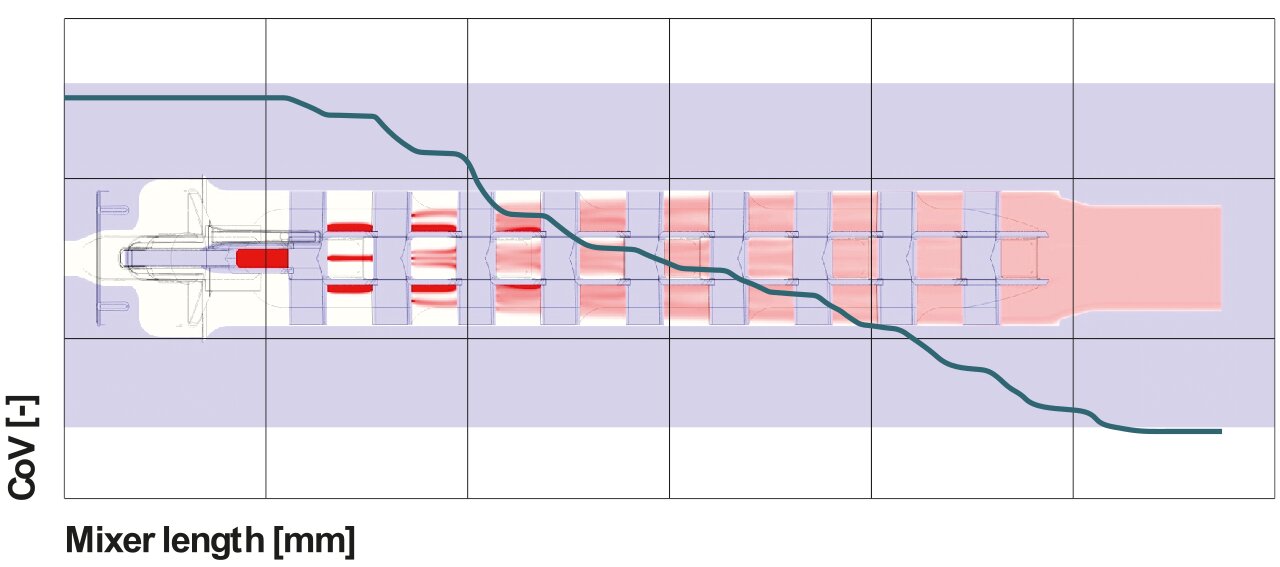

Qualitative flow analysis is often done graphically by means of contour or vector plots. Generally, the pressure and velocity field are of main interest. In the case of mixer simulations, the concentration field of the components to mix is also relevant. These plots can be analyzed to find critical areas, for example with high pressure losses or unwanted death zones with almost no flow.

Quantitative flow analysis of variables or flow parameters (for example: mixing quality or pressure loss) are generally determined at pre-defined locations within the simulation domain. For example, in simulations of static mixers the evaluation of mixing quality over the mixer length is of interest. In the case of transient simulations, these values can also be evaluated over time.

Figure 3 - Mixing quality in a static mixer

Figure 3 - Mixing quality in a static mixer

A combination of both quantitative and qualitative evaluation is shown in Figure 3. Here, the underlying image is a contour plot of the mass fraction of component B in a static mixer. The superimposed blue curve shows the progression of the CoV (Coefficient of Variation), a measure of mixing quality along the length of the mixer. While the CoV remains unchanged (no mixing) in the mixer head and mixer outlet, it decreases almost linearly in the mixing elements when the CoV is plotted logarithmically.

1.5.Advantages of CFD in comparison with measurements and its limitations

Nowadays CFD is found in almost all fields ranging from medical research to engineering. And there are important advantages because CFD is used:

- CFD can be used as a qualitative tool to pre-evaluate different designs. Designers and analysts can numerically study prototypes and then experimentally test only those that show promise. This results in significant time and cost savings.

- CFD can provide results for flow problems that are difficult to analyze by measurement or even dangerous, for example when testing hazardous substances.

- CFD offers the ability to study products or systems under conditions beyond their limits. This can be interesting to understand how a system reacts when used incorrectly.

- CFD allows flow properties to be observed without disturbing the flow itself, which is not always possible with conventional measuring instruments.

- CFD generates colorful images and graphs that help to understand the system. And finally, it can be used for marketing purposes to convince development partners of the functionality of a product.

Modern CFD solvers can handle a wide range of different physical models. However, with increasing complexity (multi-phase, multi-component, chemical reaction, ….) and highly transient behavior with phenomena sometimes even occurring on different time scales, the numerical effort to obtain a meaningful result increases dramatically. In addition, the exact fluid properties of the fluids of interest are often not known in detail or are confidential for various reasons. And even the most sophisticated CFD model is only a very good simplification of the reality.

Therefore, in many cases, measurements are still the tool of choice and a particularly important resource for validating the simulation models. It has often been shown that the best development results are achieved with a well thought-out combination of simulation and measurement.

About the author:

"Joachim Schöck has been working as a senior technology expert at Sulzer Mixpac and medmix Switzerland AG for 12 years. His main activity is the optimization and further development of high-precision application and mixing systems. This is done to a large extent using modern simulation tools such as CFD and FEM. Another focus is on the further development of test methods for predicting the mixing quality of 2K adhesives and sealants."