Expert article on the quality of MIXPAC and QUADRO greenLine products

Sustainability Without Sacrifice: Reliable Cartridge Systems for Demanding Adhesive Applications

Abstract:

Recycled plastics offer great potential for sustainable product solutions — even in technically demanding applications such as 2K cartridge systems. This article shows how medmix realizes a drop-in solution that combines performance and sustainability through structured development processes, targeted material selection, and consistent quality assurance.

Customer Expectations in Focus — Sustainability Without Compromise?

Due to public pressure and regulatory requirements, recycled plastics are gaining importance — not only in everyday items but also in technically demanding applications such as application solutions for two-component adhesives. Customers expect sustainable solutions but have understandable concerns about quality, safety, and availability. To gain market acceptance, articles made from more sustainable materials must meet the same requirements as standard articles. This can only be achieved when experience, sound material understanding, and deep expertise come together. Only when all elements — from material selection to specification to series production — are systematically coordinated can consistently high product quality be ensured.

Figure 1: Diverse portfolio of plastic cartridges based on recyclates1 [i]on the market.

Product Development is No Coincidence

In application systems, the focus is primarily on single-use product components — such as cartridges or static mixers, which, together with a durable dispensing device, form a functional overall system. These single-use components offer the greatest leverage for more sustainability. Series solutions made from recycled plastics show that ecological responsibility and technical performance are not mutually exclusive — if the right conditions are met.

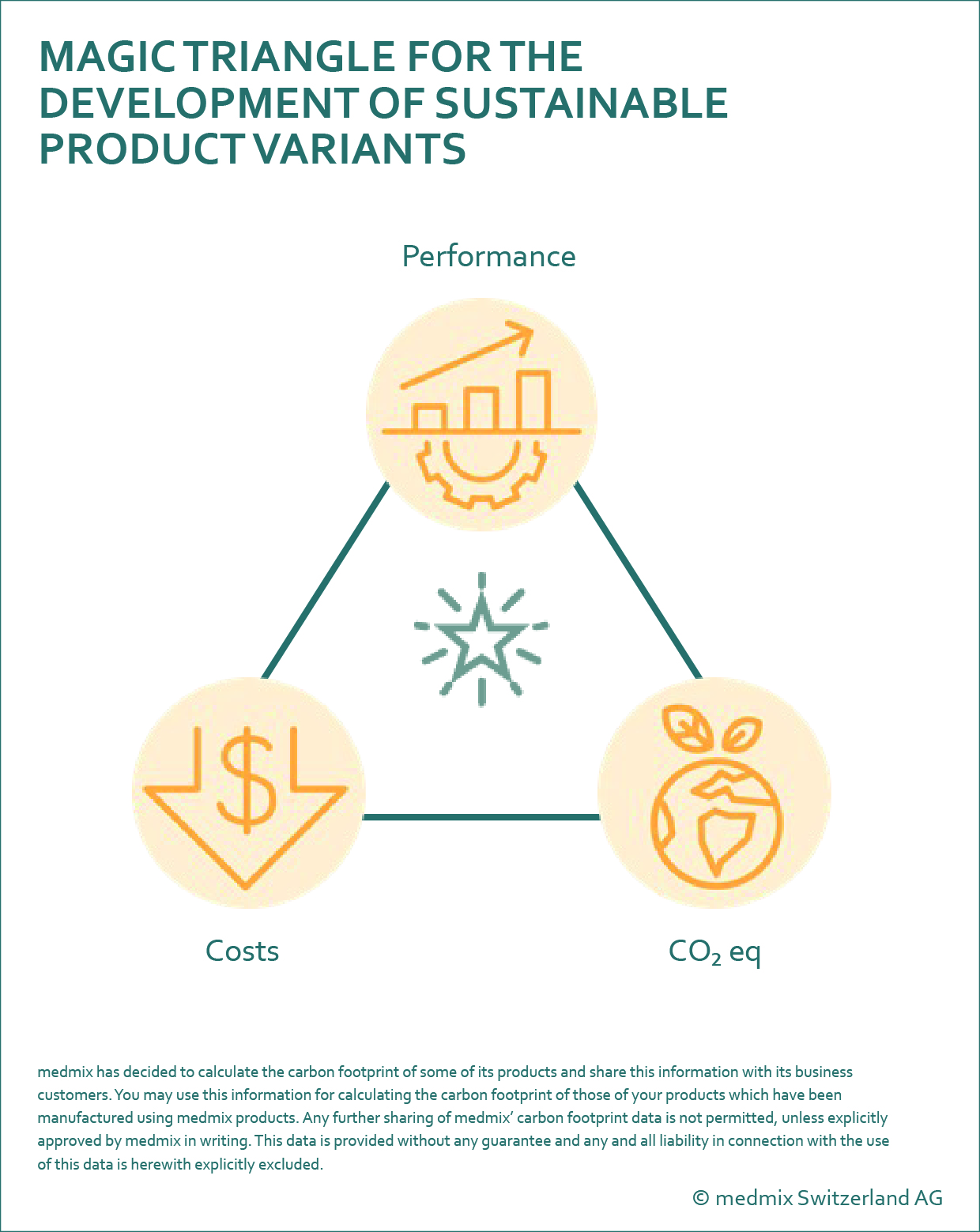

Figure 2: Magic triangle for the development of more sustainable product variants.

For such solutions to be convincing in practice, more than just the right material is needed. A structured development process that considers ecological, technical, and economic requirements from the outset is crucial.

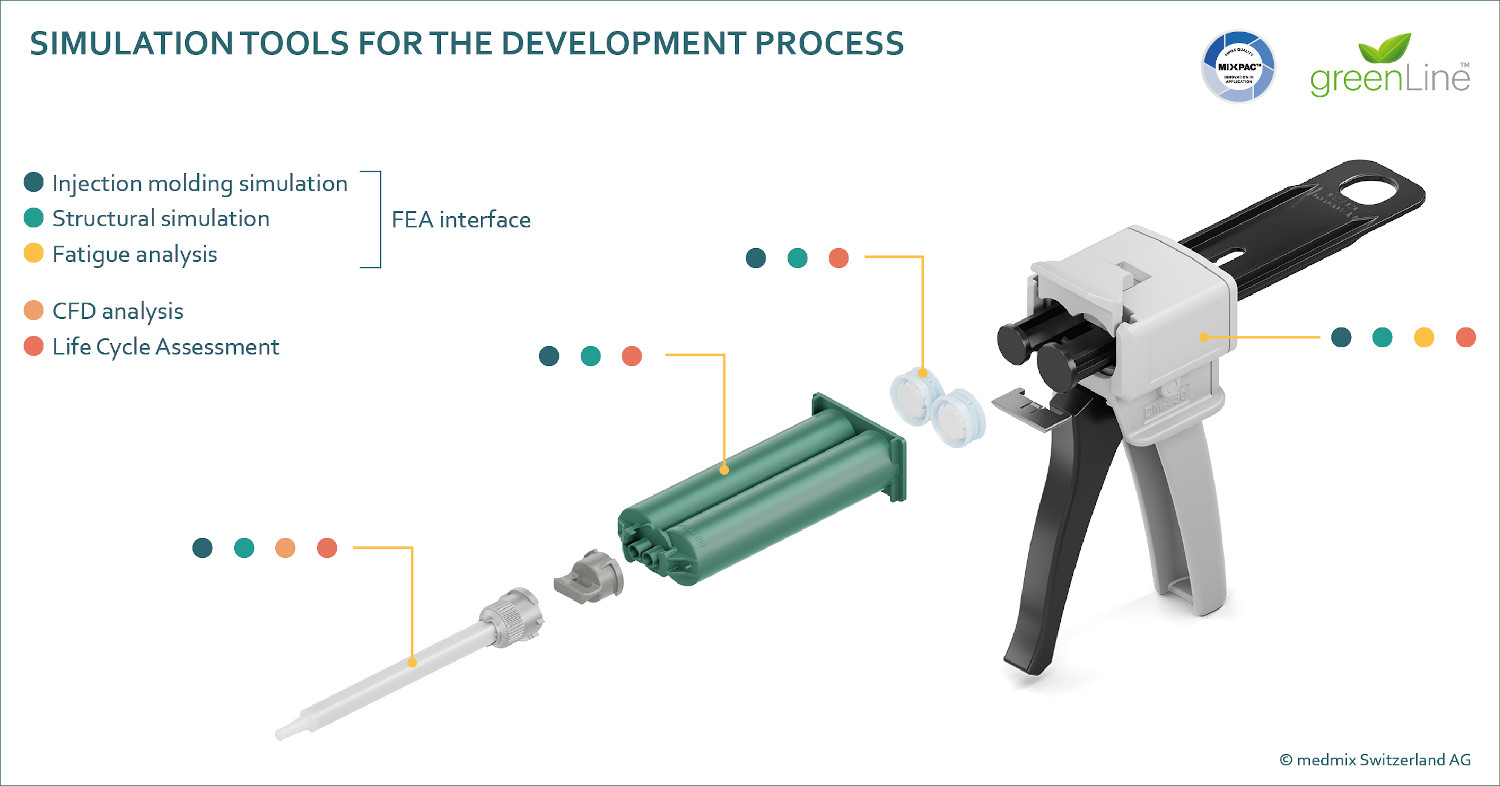

Figure 3: Simulation tools for the development process.

Material Evaluation as the Key to Success

Choosing the right material requires a thorough evaluation of potential material variants — through analytical tests, mechanical tests, and verification on real components. This requires not only comprehensive expertise but also suitable testing capacities. Both are available at medmix: On 240 m² of laboratory space, facilities for dimensional, physical, analytical, and application-technical investigations are available. Qualified external laboratories and institutes are also involved when necessary. This ensures that recycled materials meet the same requirements as conventional products.

Drop-in Solutions as an Advantage for Manufacturers and Users

With suitable recycled materials, a central approach for more sustainable product variants can be realized within the framework of so-called drop-in solutions. The existing product design is retained, while the material is replaced by an alternative — such as post-consumer recyclate (PCR). The decisive advantage: The conversion takes place using existing production means and processes, which shortens development times and significantly simplifies integration into existing systems.

For the user, this means high compatibility with established processes. The drop-in cartridges can be integrated into existing filling processes without major adjustments. The interfaces to dispensing devices, mixing systems, and closure elements also remain unchanged, enabling a smooth transition.

Figure 4: The requirements for sustainable solutions.

The results show that drop-in solutions made from recycled materials can meet the same functional requirements as their counterparts made from new materials. This offers a more sustainable alternative without compromising on performance.

Material Specification as the Basis for Series Quality

But how can the snapshots from development be transferred to the series process? A central element, as with new materials, is the manufacturer's material specification. Unlike a technical data sheet, which only provides typical material values, it defines binding tolerances for representative mechanical, thermal, and rheological properties, which are confirmed for each material batch. The relevant parameters are subsequently checked by medmix for each incoming batch using the existing laboratory infrastructure. The material specification thus forms the basis for a stable series process and contributes significantly to quality assurance.

Process Security Begins in Detail

As shown, the material decision at medmix is based on a structured development process. Starting from the product design, suitable materials are specifically selected, specified, and verified under series conditions on real components — regardless of whether it is new material or recyclate.

For the acceptance of the solution, process security is also of great importance. Therefore, a multi-stage in-process control system is established as standard, regardless of the material used, which ensures compliance with all quality characteristics in the ongoing production process.

To ensure that the quality of components made from recycled material remains constant under production conditions, this system accompanies the entire manufacturing process and starts well before the final inspection.

At regular intervals, both the quality department and trained production personnel check defined quality characteristics such as general part quality, critical component dimensions, shot weight, and compliance with functionally relevant component properties. This allows deviations to be detected and corrected early.

This consistent process monitoring is a key component in ensuring that products made from recycled plastic offer the same reliability as conventional products.

Visible Sustainability

The times when recycled plastics were predominantly available in gray or black tones are now a thing of the past. Nevertheless, the use of recyclates can lead to optical deviations, such as color differences, inclusions, or streaks. These effects are typical of the material and arise from natural fluctuations in the material stream and region-specific feedstock procurement for global products.

Figure 5: Typical deviations in plastics based on recyclates

From a technical perspective, these features are uncritical. The functional properties — especially dimensional stability, tightness, and mechanical stability — remain fully intact. Nevertheless, such visual differences require explanation for many users.

To avoid possible irritation, these features are evaluated early and actively communicated. They are part of the product description and are considered in quality assurance. This ensures that the optical appearance has no impact on the application and that customers are informed accordingly.

Recyclate Types and Their Application Limits

Recycled plastic is not just recycled plastic. For standard plastics such as polypropylene (PP) or polyethylene (PE), which are available in large quantities from used packaging, post-consumer recyclates (PCR) are preferred. For technical plastics such as polyamide (PA) or polybutylene terephthalate (PBT), only post-industrial recyclates (PIR) are currently available, as there are not yet sufficient PCR material streams for these plastic groups. The choice of the appropriate recyclate type therefore depends not only on sustainability goals but also on technical feasibility.

Recyclate Type | Origin | Application Area |

PCR (Post-Consumer Recyclate) | From used products (e.g., packaging) | Standard plastics like PP, PE |

PIR (Post-Industrial Recyclate) | Production waste, rejected goods | Technical plastics like PA, PBT |

Figure 6: Overview of recyclate types

Transparency and Trustability

In connection with the use of recyclates, the term "greenwashing" is often used — the pretense of sustainable properties without a real basis. To counter this, sustainability at medmix is part of the corporate strategy, and corresponding solutions are thoroughly verified and secured.

To make the origin and composition of the materials used transparent, supplier confirmations on the type and proportion of recycling material are available for all recyclates. In addition, external certifications are becoming increasingly important. Many suppliers are already certified according to recognized standards such as the Global Recycled Standard (GRS), EuCertPlast, or RecyClass. These certificates confirm compliance with defined environmental and quality criteria and strengthen conformity.

Regulation and Strategic Objectives as Drivers

The integration of recycled materials into industrial applications at medmix follows a declared commitment to more sustainability. A central component is the commitment within the framework of the Science Based Targets Initiative (SBTi), with which medmix commits to reducing greenhouse gas emissions along scientifically based target paths. The use of certified recyclates makes a measurable contribution to reducing Scope 3 emissions — especially in the area of single-use components such as cartridges.

In addition, regulatory developments at the European level are gaining importance. With the entry into force of the new Packaging and Packaging Waste Regulation (PPWR) in February 2025, the requirements for the use of recyclates and the recyclability of packaging are increasing. Although it is not yet definitively clear which product groups will be specifically affected, the direction is clear: Manufacturers and users are required to address the new framework conditions early.

Those who already rely on certified recycled plastics today and systematically ensure their quality and availability not only create regulatory security but also a strategic advantage in the market.

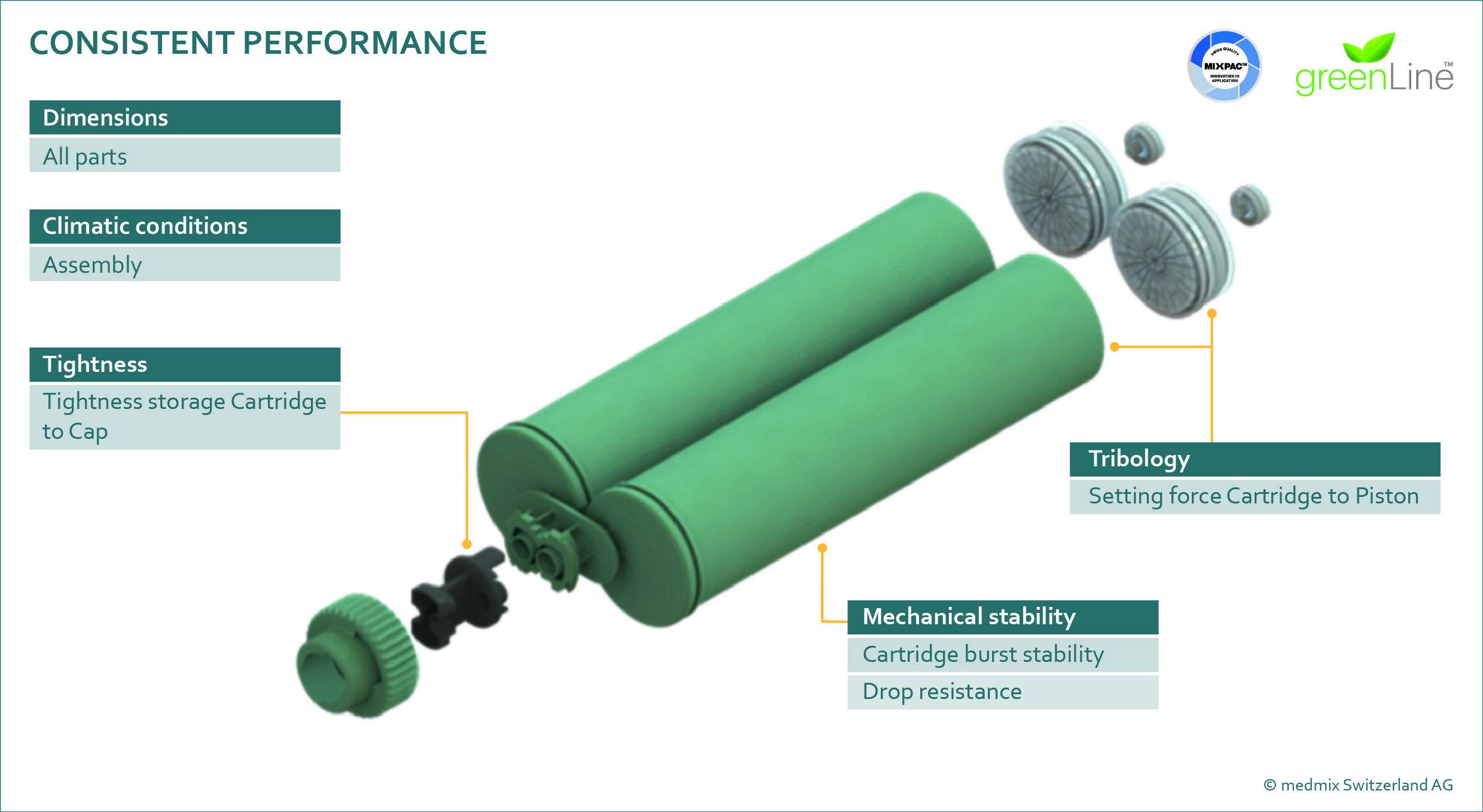

Sustainability — No Coincidence

The greenLine™ series from medmix shows that sustainability and technical performance are not contradictory. The cartridges meet all relevant requirements — from dimensional stability to tightness to mechanical stability — and enable resource-saving application without adapting existing processes. The use of recycled materials is not a coincidence but the result of a structured development and testing process that covers all aspects from simulation to material selection to series production.

With the right partner at your side, sustainability can also be realized in demanding applications — beyond classic downgrading. The continuous expansion of the greenLine™ portfolio underscores this claim. The goal is to design further applications technically and ecologically sensibly while consistently meeting the requirements for quality and system compatibility

Figure 7: Diverse Portfolio of Plastic Cartridges Based on Recyclates on the Market.

Tobias Bodenmüller

Technology Expert Sustainability

medmix Switzerland AG

Michael Kipperer

Manager Materials Technology

medmix Switzerland AG

1. At medmix we use PCR (post consumer recycled plastics) or PIR (post industrial recycled plastics) material, in which the recycled raw material is referred to as recyclate.