Comparison of static and dynamic mixing systems

MIXING TECHNOLOGY AT MEDMIX AG – For mixing 2K materials, the use of static mixers is generally the preferred choice, as they are simple in design, easy to use and relatively inexpensive. In some cases, however, static mixers do not provide the required mixing performance. Dynamic mixers offer an alternative solution for applications where either very high mixing quality or a solution for rheological demanding materials is required.

For instance, mixing and metering with static mixers proves difficult when the components have significantly different viscosities or high mixing ratios. Such applications often require a large number of mixing elements to achieve sufficient mixing quality. This results in very long mixers, which again results in high discharge forces and limited handling. In addition, these sometimes very long mixers have to be disposed of after use, which increases both the amount of plastic waste and the waste volume of the material remaining in the mixer. Due to the high pressure drop in static mixers, very high-viscose materials often cannot be discharged at the required flow rate because the discharge devices (guns or dosing machines) do not provide the required discharge forces.

1.1.Advantages of dynamic mixers

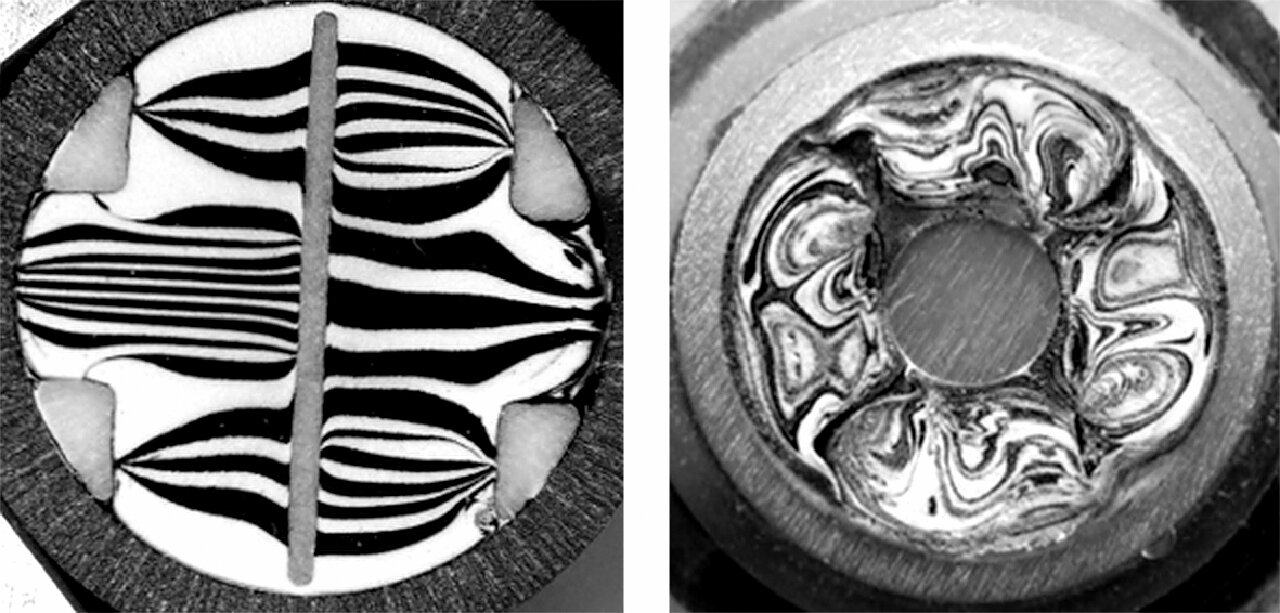

Dynamic mixers overcome these problems. In contrast to the aligned layered mixing pattern of statical mixers create the rotating blades of dynamic mixers a chaotic multi-directional pattern which enables fast dispersion and mixing (see Figure 8).

-vs-dynamic-(right)-Dynamic-mixing-allows-multi-directional-mixing-and-dispersion-1280x613.jpg?language=en) Figure 1 - Typical mixing pattern in static (left) vs dynamic (right). Dynamic mixing allows multi-directional mixing and dispersion

Figure 1 - Typical mixing pattern in static (left) vs dynamic (right). Dynamic mixing allows multi-directional mixing and dispersion

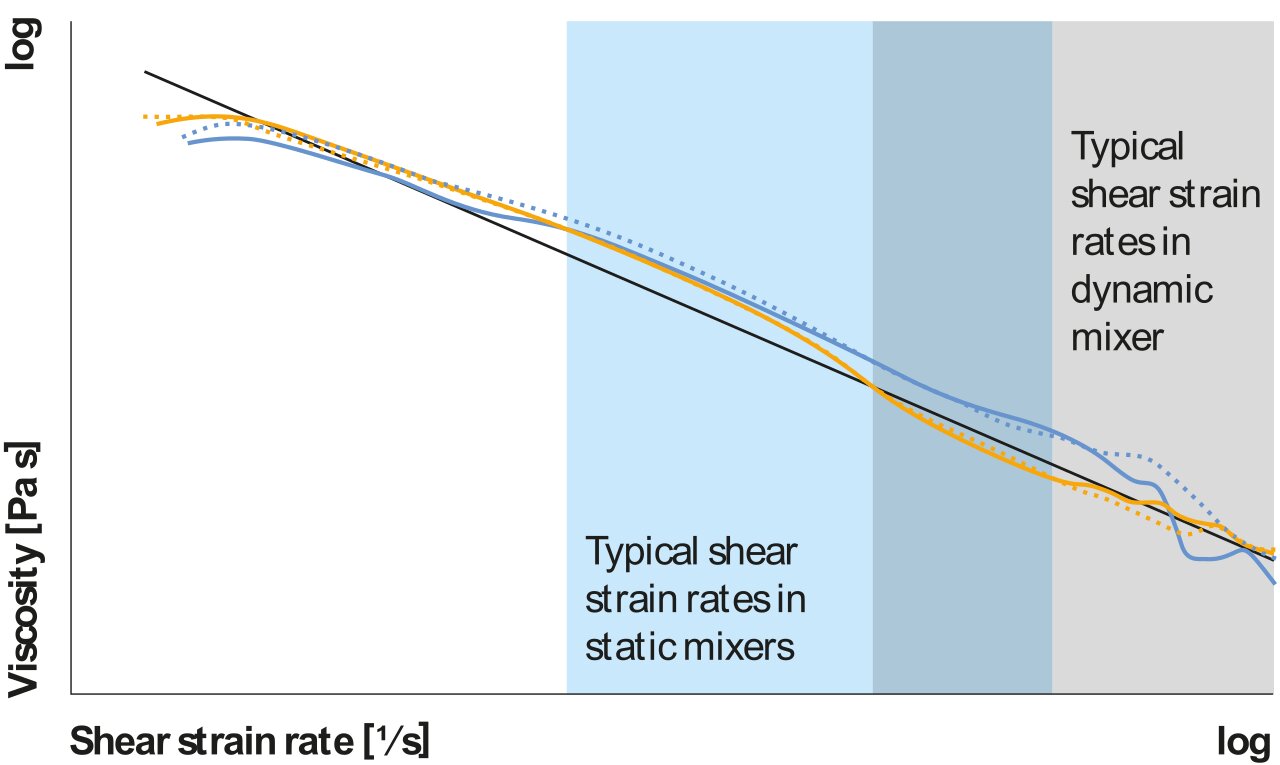

For materials with a high mixing ratio or with significant viscosity differences, this prevents the so-called channeling effect. Channeling describes the compression of the lower-viscus component by the higher-viscous component and the formation of narrow channels through which the thinner component is forced through the mixer at high speed and almost unmixed. In addition, the fast rotating blades in dynamic mixers lead to high shear rates in the mixer. Due to the higher shear energy, this not only leads to faster mixing, but in the case of shear-thinning materials also significantly reduces the viscosity and thus the metering force by orders of magnitude. Figure 9 impressively illustrates this behavior in dynamic mixers by means of the viscosity curve of a typical adhesive.

Figure 2 - Rheological behavior of a typical shear-thinning material. Light blue and grey area indicate typical shear rates of static and dynamic mixers

Figure 2 - Rheological behavior of a typical shear-thinning material. Light blue and grey area indicate typical shear rates of static and dynamic mixers

Dynamic mixing thus increases mixing efficiency on the one hand and reduces pressure loss on the other. Therefore, comparable dynamic mixers have a more compact design, which in turn leads to less plastic waste, less loss volume and better handling (shorter mixer). The lower pressure drop in the axial direction also allows very high-viscose material to be metered.

1.2.Applications of dynamic mixing systems at medmix

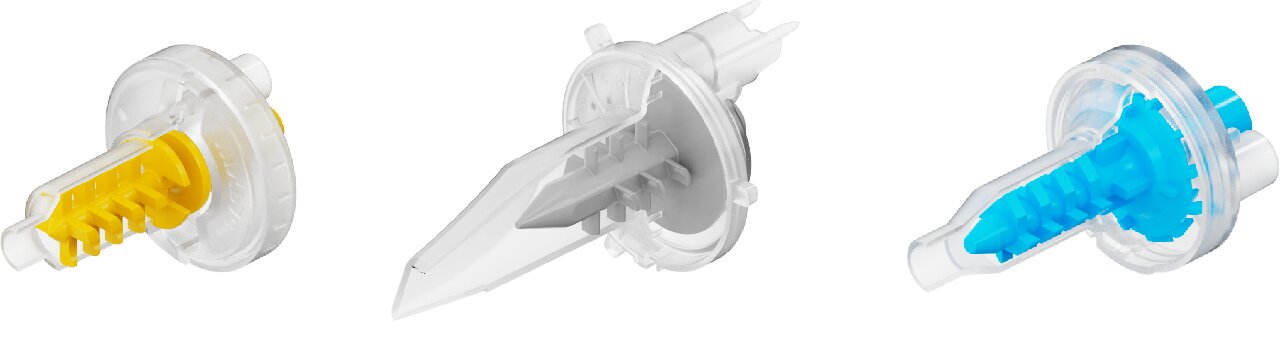

Dynamic mixing systems are widely used in metering machines to mix high-viscose 2-component adhesives or silicones with high mass flow. In such applications, mainly metal mixers are used which are cleaned or flushed after each usage. To avoid flushing with expensive material and time-consuming cleaning, some applications use disposable dynamic mixers, also. But there are also cartridge-based applications where dynamic mixing systems are used. medmix offers systems for both dental and industrial segments.

Figure 3 - Examples of dynamic mixers in the medmix® portfolio

Figure 3 - Examples of dynamic mixers in the medmix® portfolio

In the dental segment medmix® provides a dynamic system to apply high-viscose material into trays to support dentists in the production of highly accurate dental impressions. These materials are often offered with a 5 to 1 mixing ratio. In collaboration with Sika a dynamic mixer optimized for extreme mixing ratios (50:1) has been developed to enhance the application quality of Sika’s Booster/PowerCure technology. The mixer applies a range of sealants and adhesives based on polyurethane; silane terminated polymer as well as silicone chemistry. It’s used mainly in the automotive industry and for glazing applications.

1.3.Why are dynamic mixers less common than static ones?

Despite the unchallenged advantages, there are only a few cartridge-based applications where dynamic mixing systems are used. The reason is the more complicated design of the dispensing system needed. Since dynamic mixers require an additional drive to rotate the mixer blades, this must also be housed in a discharge unit, making them heavier, more unwieldy, and more expensive. In addition, finding the optimal combination of flow rate and rotational speed can be challenging and needs additional training of the operator. And especially for industrial applications the ease of operation and cost competitiveness is often a key criterium. In short, dynamic mixing increases mixing quality, reduces waste, and improves application accuracy due to the reduced overall length of the mixer, but at the expense of additional complexity and cost. Therefore, dynamic mixing systems are used for applications where no other solution is possible to accomplish the mixing task or where the benefits outweigh the additional cost and effort.

About the author:

"Joachim Schöck has been working as a senior technology expert at Sulzer Mixpac and medmix Switzerland AG for 12 years. His main activity is the optimization and further development of high-precision application and mixing systems. This is done to a large extent using modern simulation tools such as CFD and FEM. Another focus is on the further development of test methods for predicting the mixing quality of 2K adhesives and sealants."