- Oil and Gas

- Stripe Coatings

- Sewer Repair / Crack Repair

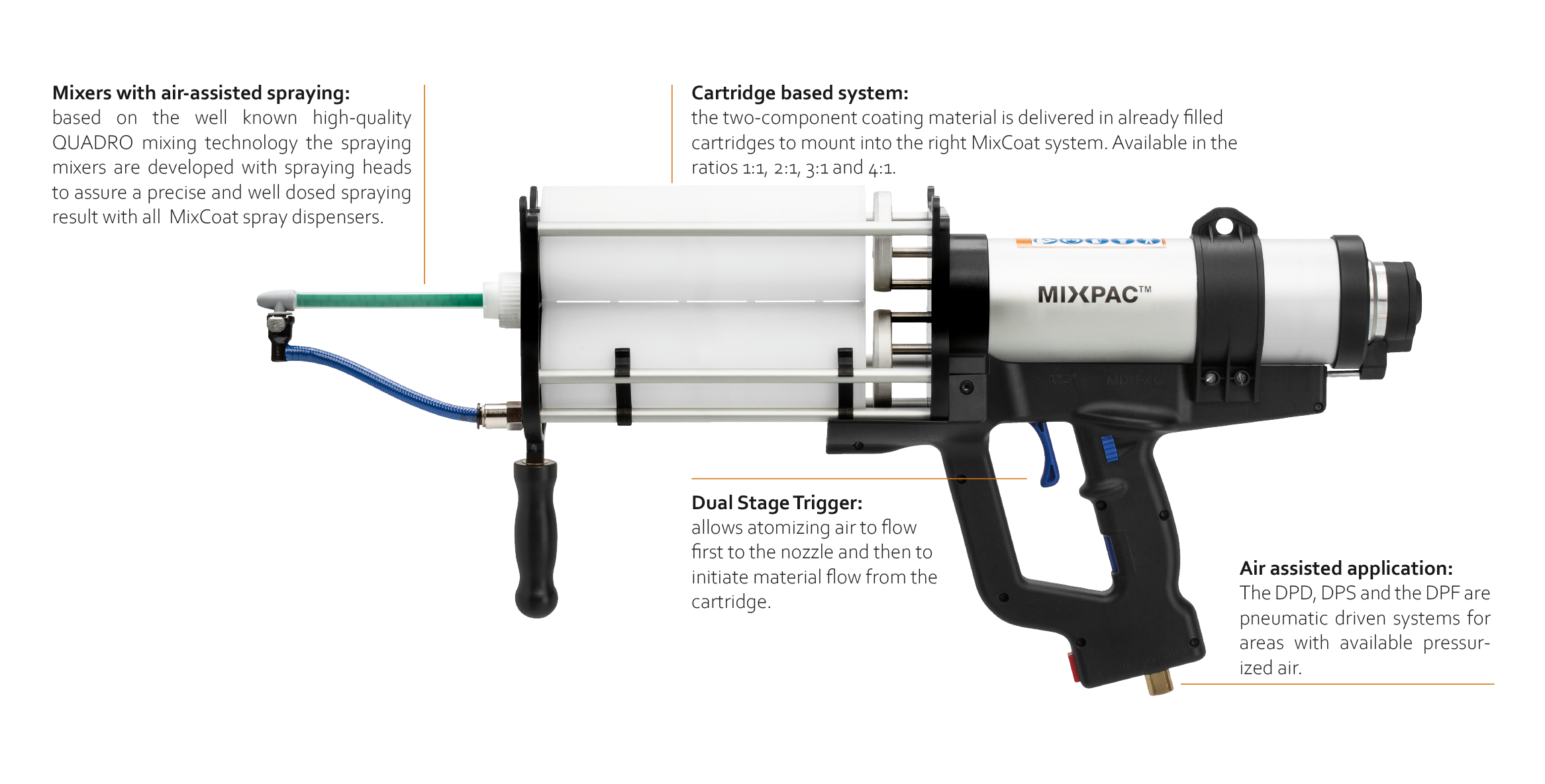

The MIXPACTM MixCoatTM Cartridge based handheld application system for two-component coatings for efficient, clean and cost optimized repair work.

Use it with manual force or pneumatic power with different application accessories from brush to spraying.

“The MIXPAC MixCoat System offers precise application and efficient mixing of two-component coatings, making it ideal for pipeline repair and other protective coating segments. Its flexibility and ease of use ensure consistent results even in challenging environments, enhancing the durability and performance of the coatings applied.”

MIXPAC Systems technology:

MIXPAC MixCoat systems:

Heat resistance:

Fully compatible mixers according to the QUADRO and MIXPAC technology with F-System interfaces

QUADRO MFQA (spraying)

Hose extension for DPS and Hybrid system

Here are some downloads with more information: Get the MixCoat catalogue, various expert articles and case studies on the use of MixCoat systems from customers for different applications.